ZIPOL-H, Metal-Oxide, Gapless

Silicon Housed Surge Arresters

ZIPOL-H

Governing Specifications : IEC 99-4, TS EN 60099-4

Nominam Discharge Current (ln) : 10kA (8/20 µs-wave)

Distribution Class, Heavy Duty rated Votage : 6 – 36 kV rms

Pressure Relief Capability : B, 20kA rms, sym

Energy Absorption Capability : 2.5 kJ/kV

Installation Site : Outdoor , 0-1200 mt. Altitude

Long Duration Current Impulse : 250 A, 2000 µs

IEC Line Discharge Class : 1

High Current Impulse Withstand : 100 kA-peak (4/10 µs)

Rated Frequency : 50 Hz

The leader of the surge protection industry in Turkey, DİSAŞ now manufactures metal-oxide arresters in polymeric (silicone) housing within its ISO-9001 Quality management System certified by Turkish Standards Institution (TSE).

Polymeric Housing

Polymeric housings, made of high quality silicone and manufactured at Disaş facilities can maintain their hydrophobicity and withstand capability against ultraviolet exposure under most severe atmospheric conditions. At the same time, their special design prevent moisture ingress thanks to their high sealing performance.

ZIPOL arresters provide the user with technical advantages as compared to arresters in porcelain housing as follows

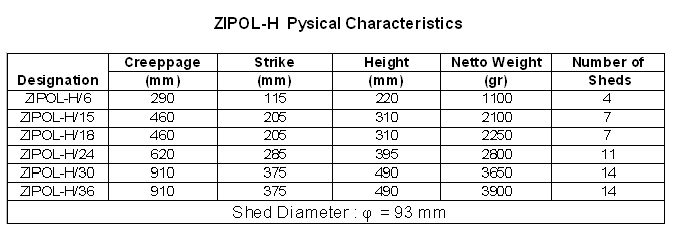

- increased leakage distance with special sheds

- ease of transport and installation facilities by lightweight of arrester

- resistance against damages from shipping, handling and vandalism.

ZIPOL arresters, made of sprecially designed stack of varistors and silicone housing, offer both excellent protective and physical characteristics.

Varistors

Varistors, supplied by one of the world's leading manufacturers of metal-oxide blocks, are being tested at disaş labs upon arrival, in accordance with international standards. Varistors are then put together by means of an epoxy-based wrapping system, to form one single and rigid column of M.O. blocks. This special design not only ensures a high withstand capability against high current surges and high physical strength, but also enables to maintain the thermal characteristics over a long period of time and to keep varistors within the wrapped stack during an arrester's failure.

Ground Lead Disconnector (GLD) & Insulating Bracket (Optional)

ZIPOL arresters, if required by the client, can be equipped with a “Ground Lead Disconnector” (GLD) which prevents lockout by diconnecting a failed arrester from the system and serves as a indicating device that the failed arrester needs replacement. “Insulating Bracket” is a necessary part, when an arrester is fitted with a GLD, as it provides insulation between the arrester and ground, after GLD has operated during an arrestor failure. Insulting bracket, with increased mechanical strength due to its specially shaped sheds, can be used for mounting the arrester either with studs and nuts supplied with each arrester as standard or by using NEMA crossarm brackets, supplied optionally.

Tests

Disaş labs are capable of performing all “routine” and “acceptance” tests determined in the international standards. All varistors and polymeric housings used in ZIPOL arresters go through “routin” tests before arresters are assembled within the manufacturing processes of ISO-9001 quality management system. Complete ZIPOL arresters then undergo all routine tests according to the standards and every arrester satisfying ISO-9001 quality management system, is ready for shipment.

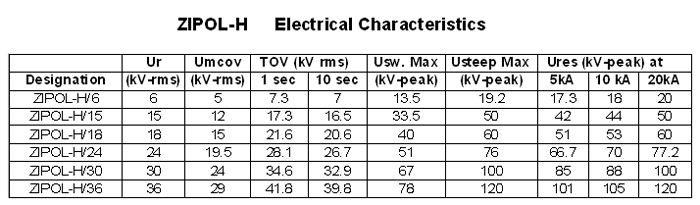

Ur : Rated Voltage

Umcov : Max. Continuos Operating Voltage of the Arrester

Usteep : Steep Current Impulse Max. Residual Voltage(1/20 µs-wave)

Usw : Switching Current Impulse Max. Residual Voltage (30/60 µs-wave)

Ures : Lightning Impulse Current Residual Voltage (8/20 µs-wave)

TOV : Temporary Overvoltage Capability

Installation Options: 1 - No insulating bracket, base-mounted

2 - No insulating bracket, with metal bracket

3 - Insulating bracket and Disconnector

4 - Insulating bracket, Disconnector and NEMA-mounting bracket

Standard: M10 line and earth terminals, clamp connection suitable for 16-70mm² alu. Or copper stranded-conductor.